Induction brazingis a process in which two or more materials are joined together by a filler metal that has a lower melting point than the base materials usinginduction heating.

There are specific reasons to use induction heating for industrial brazing. These include selective heating, better joint quality, reducedoxidationand acid cleaning, faster heating cycles, more consistent results and suitability for large volume production.

Induction heating can be targeted to provide heat to very small areas within tight production tolerances. Only those areas of the part in close proximity to the joint are heated; the rest of the part is not affected.

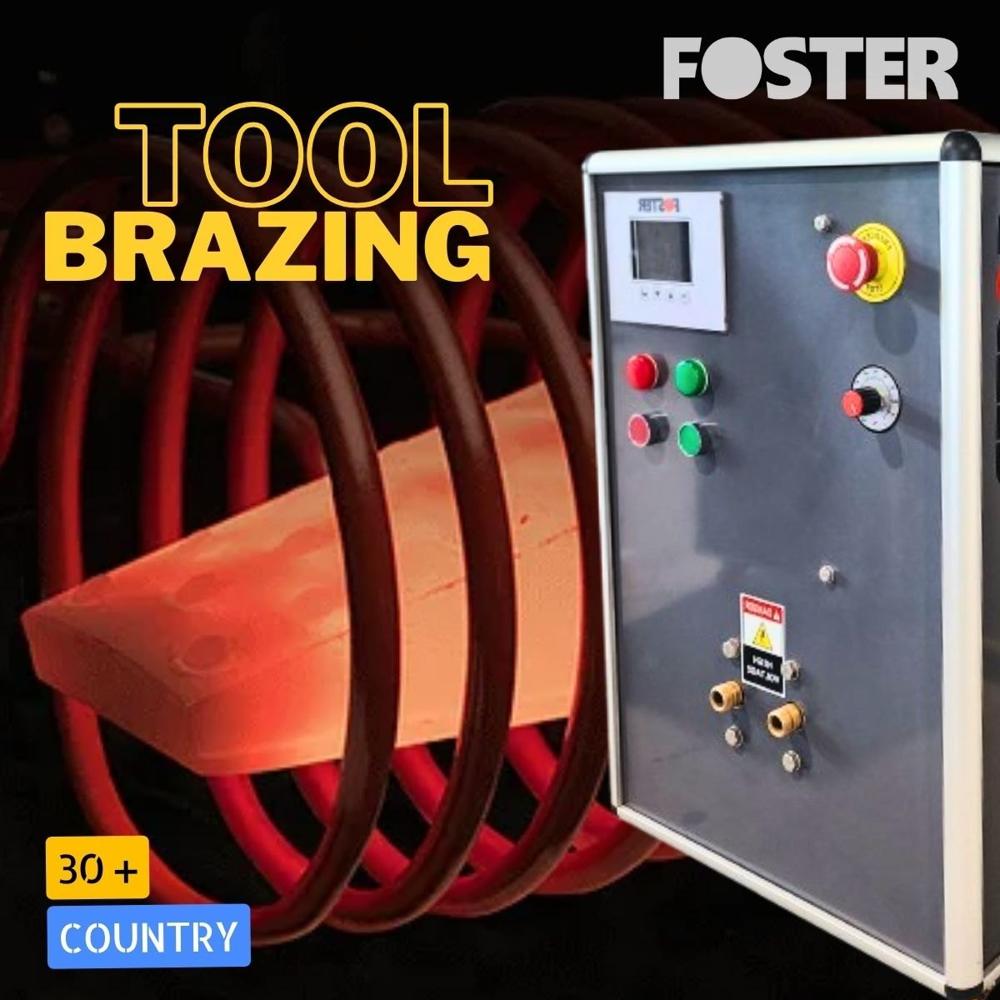

Foster Induction heating produces clean, leak proof joints by preventing the filler from flowing in areas that it shouldn't flow. This ability to create clean and controllable joints is one of the reasons that induction brazing is being used extensively for high-precision, high-reliability applications.

Because the induction heating cycle is very short in comparison to flame brazing, more parts can be processed in the same amount of time, and less heat is released to the surrounding environment. An induction brazing system quickly delivers highly localized heat to minimize part warpage and distortion.

Foster Induction brazing systemis a very repeatable and accurate process because variables such as time, temperature, alloy, fixturing, and part positioning are very controllable. The internal power supply of the RF power supply can be used to control cycle time, and temperature control can be accomplished with pyrometers, visual temperature sensors or thermocouples.

100% Make in India

CUSTOMIZED SOLUTIONS ARE OUR SPECIALTY

NEED A QUOTE?

SPEAK TO OUR

SALES ENGINEER NOW