About Induction Annealing Furnace

Foster Induction Induction Annealing Furnace (Wire Annealing / Stress Relief Furnace)

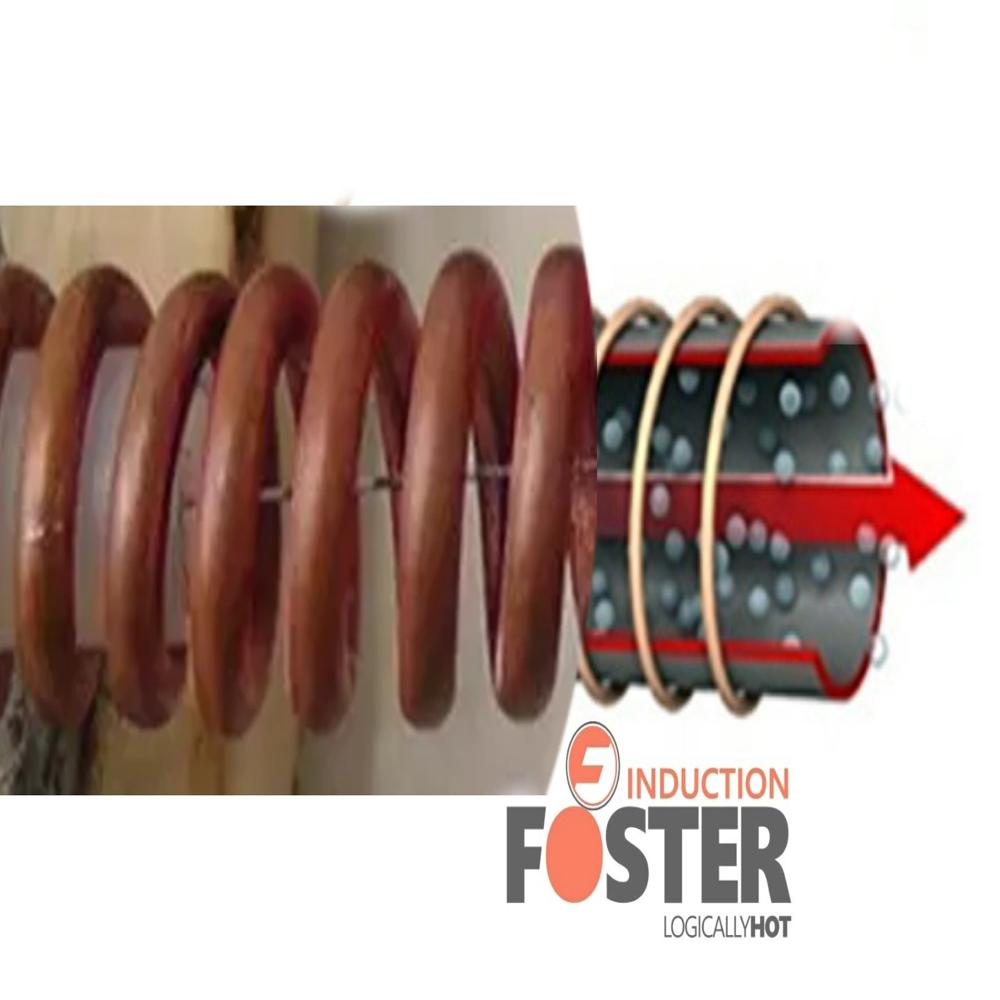

Foster Inductions annealing furnace uses IGBT-based mediumtohigh frequency induction heating technology to rapidly heat wires, strips, and other conductive materials for processes like annealing, stress relief, tempering, and bright annealing.

Key Features:

- Fast, uniform heating via electromagnetic induction (eddycurrent & hysteresis-based) ensures quick temperature ramp-up without direct contact or open flame .

- Precise digital control: microcontroller / PLCbased temperature and time settings allow consistent, repeatable outputs .

- For nonferrous and ferrous materials such as copper wire, strip, and steel elementswith customizable power and coil geometry .

- Safety & efficiency: automated control lowers operator risk; IGBT inverter design minimizes energy loss; compact, clean and ecofriendly.

Typical Use Cases:

- In-line annealing in manufacturingsuch as copper/ aluminium wire extrusion linesto relieve stress or prepare material for further processing.

- Stress-relief and bright-annealing of metal parts, minimizing microstructural defects and enhancing ductility or machinability .

FAQs of Induction Annealing Furnace:

Q: What condition is the Induction Annealing Furnace available in?

A: The Induction Annealing Furnace is available in new condition.

Q: What color is the Induction Annealing Furnace?

A: The Induction Annealing Furnace is available in black color.

Q: What voltage range does the Induction Annealing Furnace require?

A: The Induction Annealing Furnace operates within a voltage range of 220-415 Volt (v).

Q: Is the Induction Annealing Furnace suitable for industrial usage?

A: Yes, the Induction Annealing Furnace is specifically designed for industrial usage.

Q: What is the warranty period for the Induction Annealing Furnace?

A: The Induction Annealing Furnace comes with a warranty period of 1 year.